Tech Specs

Product information

Clear Flex™ 50

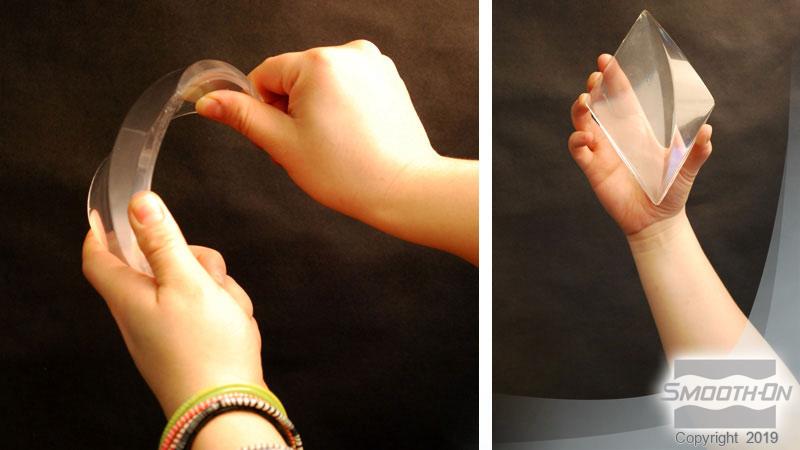

Clear Flex™ 50 is a water white clear urethane liquid rubber compounds designed for applications that require absolute clarity and resistance to sunlight. Low viscosity ensures easy mixing and pouring. Clear Flex™ 50 will cure at room temperature with negligible shrinkage.

CAUTION: NOT FOR HOME USE. THIS PRODUCT IS FOR INDUSTRIAL USE ONLY. With adequate local exhaust ventilation, respiratory protection is not normally required when using this product. Where risk assessment shows air-purifying respirators are appropriate, follow OSHA respirator regulations and European Standards EN 141, 143 and 371. Protective clothing (gloves and long sleeves) is required to minimize the risk of dermal sensitization. If breathing is affected or a dermal rash develops, immediately cease using this product and seek medical attention. Read SDS before using.

Features

Cured castings are:

- Clear

- Flexible

- UV Resistant.

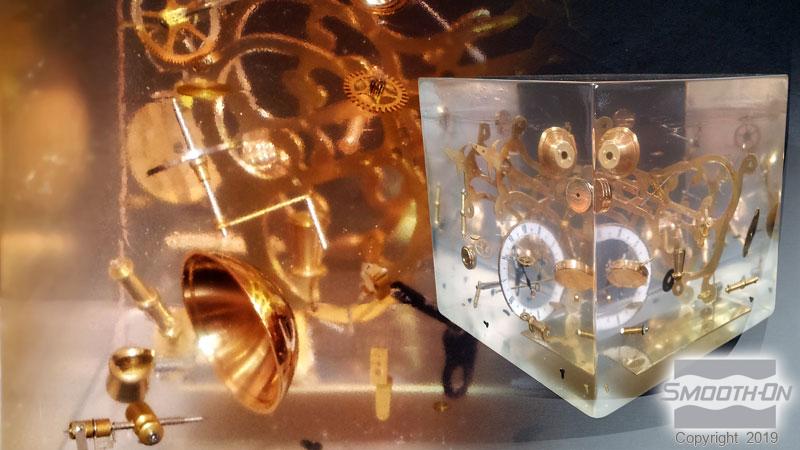

Vibrant colors and color effects are achieved by adding pigments. Applications include making clear-cut molds, model reproductions, decorative cast pieces, special effects, prototype parts.

Instructions

Safety - Store and use at room temperature (73°F/23°C). These products have a limited shelf life and should be used as soon as possible. Environmental humidity should be as low as possible. Good room size ventilation is essential. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Wearing a NIOSH approved respirator will minimize inhalation of residual fumes.

Some Materials Must Be Sealed - To prevent adhesion between the rubber and model surface, models made of porous materials (gypsum plasters, concrete, wood, stone, etc.) must be sealed prior to applying a release agent. The best sealer for sealing porous materials is SuperSeal™ or One Step™ (Available from Smooth-On). Spray shellac is suitable for rough contours. A high quality Shellac is suitable for sealing modeling clays that contain sulfur or moisture (water based). Allow sealer to dry thoroughly.

Applying A Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent (such as Universal™ Mold Release). A liberal coat of release agent should be applied onto all surfaces that will contact the rubber.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let dry for 30 minutes.

Selecting A Mold Rubber - Pour into a urethane rubber mold (Vytaflex™ urethane – release agent required), tin cured silicone mold (Mold Max™ 10, 14NV, 20, 25, 30 or 40 silicone) or Mold Star™ 15, 16 or 30 platinum cured silicone mold. Clear Flex™ 50 will not work in a Mold Max™ 10T, 15T or 20T silicone mold.

If using Mold Max silicone; to prevent cure inhibition, post-cure newly silicone mold for 8 hours at 60° C / 150° F and let cool prior to casting resin. If you are unsure about surface compatibility, a small scale trial casting should be made.

For Best Results Before Pouring Clear Flex™ Into Mold: Pre-heat rubber mold at 212°F / 100°C for 4 hours. This will minimize chances of fish-eyeing, suck back, corner rounding, large bubbles, etc. in finished casting.

Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic. Materials should be stored and used in a warm environment (73°F/23°C).

IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT™ Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.

Pre Mix the Part B before using. Before you begin, pre-mix Part B thoroughly to re-disperse pigments that may have settled. Using a gram scale, dispense required amounts of parts A and B into a mixing container and mix for 3 minutes. Scrape the sides and bottom of the container several times.

If Mixing Large Quantities (16 lbs./7 kg. or more) at one time, use a mechanical mixer (i.e. turbine mixer or equal) for 3 minutes followed by careful hand mixing for one minute as directed above. Then, pour entire quantity into a new, clean mixing container and do it all over again. If coloring or filling Clear Flex™ 50, add filler or pigment dispersion to Part B and mix thoroughly before adding Part A.

Important: Material is mass sensitive and will exotherm. Large amounts of material cast at one time will generate heat and will shrink in proportion to mass. The more material cast in a large concentration, the higher the shrinkage. Amount and nature of shrinkage will depend on casting thickness and mold configuration.

Vacuuming Material - If vacuum degassing prior to pouring, your vacuum pump must pull a minimum of 29 inches of mercury (or 1 Bar / 100 KPa). Leave enough room in container for material expansion. Vacuum material until it rises, breaks and falls. Vacuum for 1 minute after material falls.

Pouring - If casting Clear Flex™ 50 into a rubber mold, pour mixture in a single spot at the lowest point of the mold. If encapsulating an object, do not pour the mixture directly over the object. Let the mixture seek its level. A uniform flow will help minimize entrapped air.

For Best Results - Best results are obtained using a pressure casting technique. After pouring the mixed compound, the entire casting assembly (mold, dam structure, etc.) is placed in a pressure chamber and subjected to 60 PSI (4.2 kg/cm2) air pressure for at least two hours.

Post Curing - Castings will cure faster and achieve maximum physical properties and heat resistance if Clear Flex™ 50 or Clear Flex™ 95 is post cured. Post curing is recommended if castings are thin or low mass concentration. Castings should be post cured in a mold or support structure.

Post Cure Schedule: Allow the material to cure for 6–8 hours at room temperature followed by 16 hours at 150°–160°F (65°–72°C). Allow casting or part to cool to room temperature before demolding.

For most applications, room temperature curing (73°F/23°C) for 24–48 hours is adequate. Castings will reach ultimate physical properties at room temperature in 5–7 days. Castings removed from mold before 12 hours may exhibit a tacky surface that can be eliminated by exposing casting to 150°F/65°C for 4–6 hours. If you are pouring less than 1/4 in. / 0.64 cm of material, the casting should be heat post cured.